Automotive

Capacitive touch controls and in-mold electronics for automotive applications

We design and produce versatile and robust capacitive touch sensors and in-mold electronics (IME) that are specifically designed for automotive applications. We deliver tailor-made control solutions, PTC heating elements, film antennas and printed sensors to enhance innovation in car interior and exterior surfaces.

Touch controls for automotive applications

Touch control technology and smart surfaces rapidly become the new standard in car interior interfacing. Not surprisingly, because they bring a variety of benefits to automotive controls:

- Innovative design: Mechanical knobs and buttons can be replaced by sleek and smooth tablet-like touch interfaces.

- Reduced complexity: The production process of touch controls is more cost-effective compared to the production of mechanical parts.

- Increased robustness: The one-piece design of touch technology reduces the risk of impact damage such as loose components or broken connections.

- Smart surfaces: By adding touch control technology, vehicle interior modules become ‘smart surfaces’ that offer additional functionality and comfort.

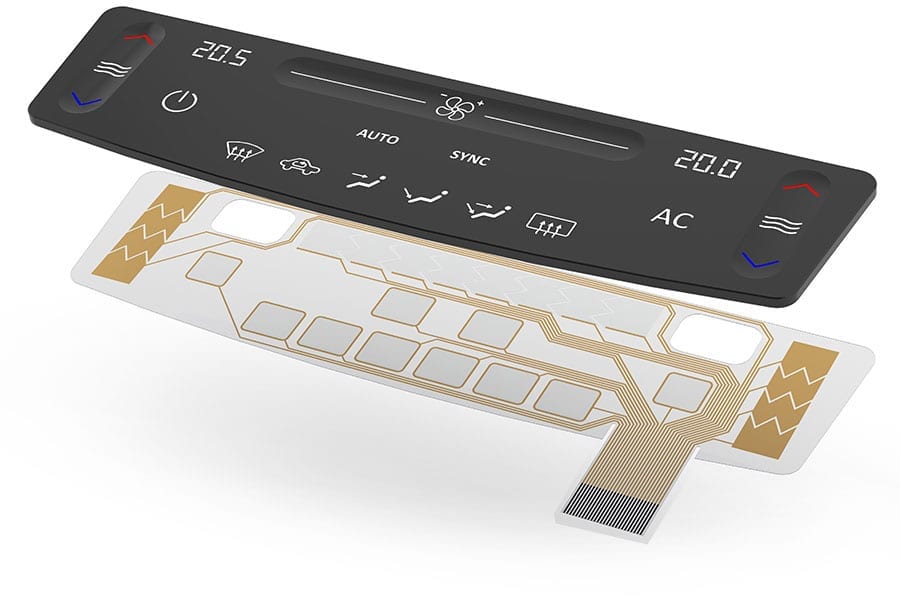

Our touch sensors can hold a combination of graphic printing (colours and diffusors) and conductive printing for touch buttons, sliders, wheels, etc.

We develop capacitive touch sensors to match any automotive HMI application, from HVAC controls to steering wheel commands to overhead panels. When designing a capacitive touch panel, we take into account your specific requirements.

Touch sensors of the next generation

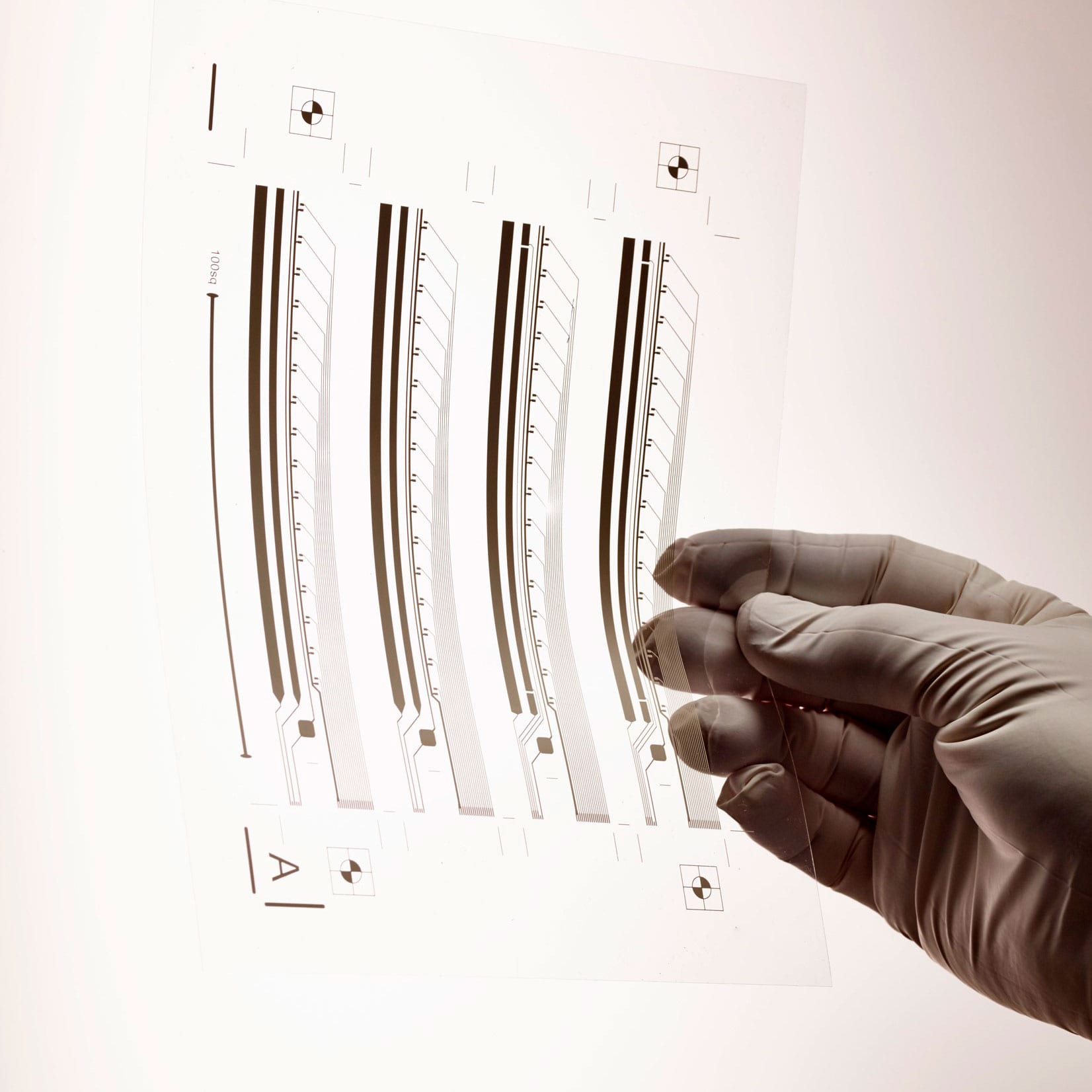

For the development of our capacitive touch sensors we use the most innovative inks that offer the highest sensitivity. Our conductive inks are well suited for fine line printing and high resolution. They excel in cost vs. performance ratio.

Black panel effects

By integrating our thin, flexible sensors behind dark, yet translucent cover materials you can create a visually stunning ‘black panel effect’. It allows you to create sleek touch controls with symbols and icons that remain hidden until the engine is started or the corresponding touch sensor is activated.

Smooth backlighting

By applying backlighting to your touch panel, you communicate with occupants through a clear visual feedback.

We screen-print capacitive touch sensors with both transparent- and non-transparent conductive inks. The combination allows to transmit light from the underlying LEDs. It enables you to achieve an aesthetically attractive touch HMI with clear and effective visual feedback. It is the perfect cost-effective solution for all car manufacturers.

Exquisite design

Our capacitive touch sensors are compatible with most cover materials, such as glass, plastic, leather and wood. The integration of our sensors in these materials makes surfaces really come to life.

Our flexible design approach allows us to deliver the touch sensor solution that you need.

In-Mold Electronics

Together with our partner, Novares, we develop In-Mold Electronics for automotive applications. IME parts are thin, stylish, 3D shaped functional parts. Each part is a seamless one-piece structure that replaces multipart assemblies of traditional electronics. It is a great way to add freedom to your HMI design.

The manufacturing process includes printing, pick-and-place (SMT) assembly, thermoforming and injection molding. Within the partnership of Novares and Quad Industries we offer the complete manufacturing process.

Quad Industries participates in Novares’ open innovation lab, Nova Car, by integration printed touch controls that lead to an advanced user experience.

Are you looking for a flexible partner for the integration of touch sensors in your automotive application?

PTC heating elements

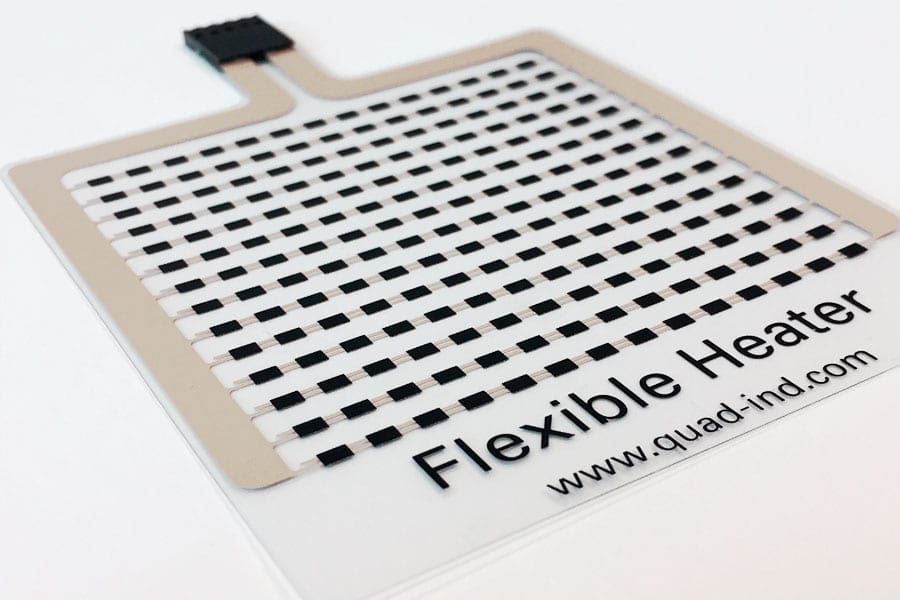

Our PTC heating elements are used in a wide variety of radiative car interior heating systems, ensuring a sufficient and comfortable temperature in the passenger compartment. They can be easily built into customized modules and surfaces, for example for steering wheel or armrest heating.

PTC elements enable fast and even heating of the surface, while avoiding any risk of overheating. Because they are extremely thin, they are built into small, flat or curved spaces and surfaces.

Heating elements are also integrated in more technical parts, such as battery packs and in the motor compartment of vehicles. Our flexible PTC elements can be integrated in any fluid tank containing oil, cooling liquid, AdBlue, or another liquid. That way, motor fluids can be kept at the ideal temperature, improving the overall performance and fuel economy of the vehicle.

Printed sensors

Modern vehicles are equipped with different sensors to measure and manage the performance and driving conditions of the vehicle. Battery packs of hybrid and full electrical vehicles are equipped with heat and humidity sensors. Our printed sensor technology is compatible with all the latest car manufacturing technology. We develop flexible sensors that can be efficiently integrated into any surface or component.

Film antennas

Our printed film antennas are extremely thin, allowing them to be easily integrated into the roof or under the spoiler of the vehicle. Because of their flexibility, the film antennas can be adapted to any form or design, without the hassle of complex cable harnesses. The antennas can be designed to support different signalling technology such as GNSS, FM and DAB.

Why Quad Industries?

At Quad Industries we design, develop and produce capacitive touch solutions, PTC heating elements, printed sensors and film antennas for automotive applications.

- Our expertise and technical knowledge are your guarantee for reliable solutions that meet all your needs.

- Thanks to our cost-effective production process we can offer very competitive prices.

- In our modern and clean production facilities, we are able to integrate the most innovative technologies in your product.

- We offer solutions that are in line with IATF 16949.

Contact our experts to see how we can help you in every phase of your production process: from R&D, engineering and prototyping to co-creation and manufacturing.