Printed sensors

The building stones for smart products

Printed sensors are the primary building stones for the development of the Internet of Things and creating smart products and objects. They enable monitoring of anything from temperature and moisture to pressure and motion. Quad Industries helps its customers – both start-ups and established companies – to turn innovative ideas into products that are ready to market.

“Developing smart products is more than just adding sensors to your existing product.”

Let’s make it smart with printed electrodes!

The advent of the Internet of Things is driving the demand for smart and interconnected objects and products in every sector – from the worlds of sports and fashion to automotive and healthcare. The rapid development of flexible screen-printed electrodes enables to integrate sensors in a wide range of products where this was not technically feasible even a couple of years ago – think plastic packaging, clothing, sport shoes or even mattresses.

Turning your ideas into working products

Developing smart products is more than just adding printed sensors to your existing product. It requires making the right choices, both technical and functional. We use our expertise to guide you every step of the way, exploring possibilities and limitations while answering a number of crucial questions. What’s the best way to integrate electronics in your specific product? How do we ensure reliability and durability? How do we set up the connection? Can it be manufactured in a cost-efficient manner? In short, we help you turn a great idea into a perfectly working product. Do you want to know how this can work for your specific products? Get in touch with Quad Industries, by filling out our contact form.

Printed sensors designed for manufacturing

Quad Industries runs its own state-of-the art production plant for manufacturing printed sensors and a wide range of other flexible electronics. This means we can not only assist you in the development of your printed sensors, but we can also take care of manufacturing – whether you are looking for small runs for prototyping purposes or large-scale production. A close link between our R&D people and the manufacturing site makes sure we fully realize the impact our choices in the development stage will have later on.

A fully customized solution

Typical applications of printed sensors

Personal health, for example sports and healthcare wearables, electronic skin patches

IoT sensors (pressure and moisture sensor)

Direct integration

- Plastic films, TPU, fabrics, paper

- Silver, copper, carbon inks. Both flexible and stretchable

- Component assembly through Pick & Place process

- Skin compatible materials

- Integration in textiles

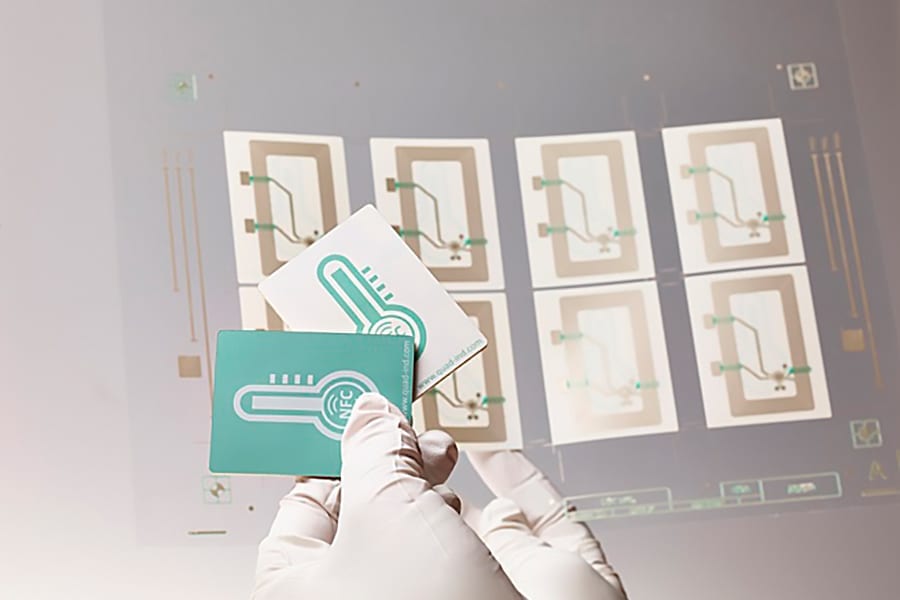

Wireless connectivity

- Printed antennas – NFC, BLE, WIFI,…

- Quad Industries provides simulation, design and manufacturing of screen-printed electrodes and sensors

Can we tempt you with a sample?

The printed sensor technology of the future now comes in a convenient test box. The Sensor INKxperience Kit developed by Henkel Qhesive Solutions in collaboration with Quad Industries, offers a hands-on experience of five different printed electronics sensor functionalities and comes preconfigured with hardware and software to provide your IoT engineers with an easy setup. Convinced? Order yours through the Henkel sample shop.

Get inspired

Unlock the potential of printed electronics with Henkel’s Sensor INKxperience Kit

Henkel has always taken the lead in revolutionizing materials and enabling the technologies of the future. To demonstrate the potential of its Loctite portfolio of functional inks for printed electronic circuits on foil and the integration of flexible printed...

Printed electronics for the healthcare industry

Printed electronics has attracted tremendous attention in recent years. Not only because it introduces new possibilities, but also because it includes properties such as flexibility and stretchability, which even enlarge these possibilities. One of the domains where...