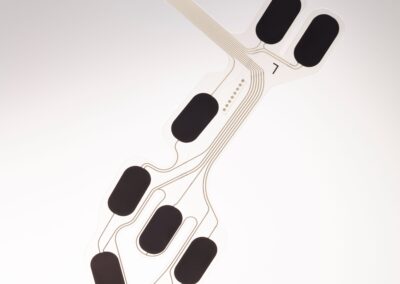

Screen printing is one of the most popular and efficient methods for applying graphics and functional inks on a wide range of substrates. It’s used to create high-quality images as functional circuits as well. Let’s give you an overview of screen printing for electronics and explore some of the benefits it offers.

First off, screen printing relies on a process called “stenciling” which involves pushing ink through a screen with a squeegee. The ink then adheres to the substrate creating a printed image or pattern. One of the most important aspects of this process is ensuring that the screen is properly aligned and that any fiducials (markers) in the corners of the screen are precisely placed. This ensures that there is layer to layer positioning throughout the substrate, allowing for accurate and consistent results every time.

In addition to these basics, screen printing requires a range of tests to ensure perfect quality. With graphical prints, this typically involves checking for color accuracy and adhesion. For functional prints, however, additional measures such as resistance testing must be done at both the process level (each production panel) and product level (end of line products). This means measuring resistance of conductive tracks to determine whether a desired target has been met.

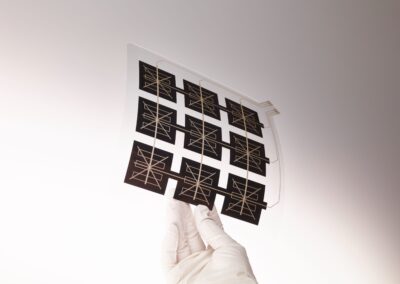

The substrates used in screen printing vary depending on the type of product being created. Polyester (PET) is one of the most common substrates, and it is often heat-stabilized to reduce distortion caused by curing or exposure to application related high temperatures. Additionally, polycarbonate (PC), TPU (thermoplastic polyurethane) and PMMA (polymethyl methacrylate) are also used in screen printed electronics.

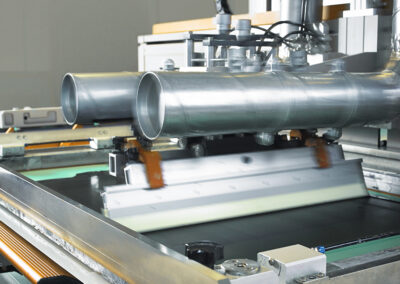

Finally, screen printing can produce prints at speeds of over 500 runs per hour with fully automated lines. This makes screen printing a great choice when you need short processing times on large quantities of products.

Overall, screen printing offers an efficient, cost-effective way to create functional prints for all kinds of applications. It’s especially well-suited for mid- to high-volume production and can be used to create both graphical and functional prints with minimal distortion. With careful attention to screen alignment, fiducials, and quality testing, screen printed electronics are sure to pass the test of time.

When you’re looking for an efficient way to scale the manufacturing of your functional prints, screen printing is an excellent choice.

The result is an attractive finished product that looks great and works well. With screen printing, you can count on top quality printed circuits that are both accurate and long-lasting. So, if you’re looking for a reliable screen-printing service for your electronics project, Quad’s screen printing is the perfect choice! Get in touch with us.