As we explained in an earlier blogpost, the most common used technique to create flexible electronic circuits is screen printing. In this blog, we will explain the crucial factors to implement screen printing the right way.

What steps do we take?

Screen printing processes involve a few key steps to create quality results. First, screen preparation requires creating stencils that will be used to transfer ink onto the substrate material. These stencils are created by stretching a fine mesh over a frame and coating it with light-sensitive emulsion or photo-imaging film which is then exposed with UV light before being washed off with water to reveal a screen pattern. A new exposure technique is computer-to-screen, in which a laser directly beams the pattern in the light-sensitive coating.

It is important to control the tension of the mesh in the frame. Too high a tension can cause the screen to tear and too low a tension will lead to deformed prints. We always run an in-house control of the mesh to make certain we don’t get any distortion of the printed image.

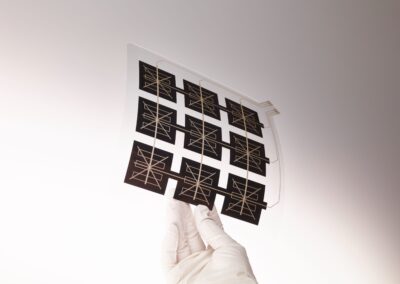

As said, UV-lighting is used to create the pattern in the mesh. If you have exposed the mesh too much to the light, you can create shadow-effects. When there was too little exposure, the complete pattern will not be etched, resulting in a poor resolution of your print result. So this is inspected in great detail, since we work with tolerances as low as 100 or 150 micrometer for high-end applications.

Applying and fixing ink on the substrate

After screen preparation, the next step is to coat the screen with ink. The first step we call flooding, in which we spread the ink over the mesh with a flood bar. This way we create a homogeneous layer on the screen. The second step is to apply pressure to push the ink through the mesh. This is done by using a squeegee. The squeegee will press the ink through the screen pattern onto the substrate and with enough pressure, it will transfer evenly.

These two steps are always repeated: flood the screen with ink, then push the ink through the mesh. With enough pressure to effectively push the ink through the screen, but not too much pressure so the mesh isn’t deformed, and the print result is accurate.

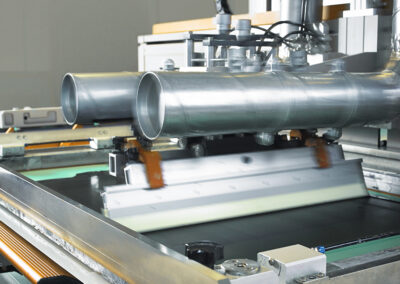

The screen-printing production continues by feeding more substrates on the printing station under the screen.

A cleaning station will first remove all dust particles from the surface of the substrate, so no particles contaminate the screen. While printing, the distance between the screen and the substrate should be minimal, again not to deform the print image. We secure this by using automated registration or by laying out registration points for each layer, in combination with vacuum systems to secure the thin film substrate in place.

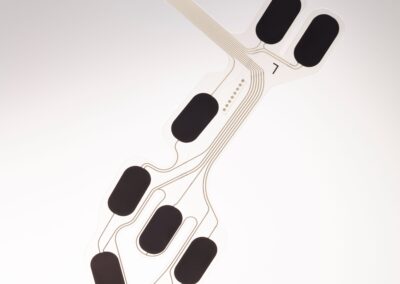

For multi-layer screen printing processes, multiple screens are used as needed and registered precisely between each layer.

Each layer can be printed semi-automatic or fully automatic. Semi-automatic means an operator will put the substrate in the press, pushes a pedal and the press will start the printing process. Afterwards the operator will manually transfer the substrate on a conveyer belt in the oven so the ink will be cured at the right temperature. In a fully automated process, all substrates are loaded on a stacker, and will be fed through the press on a belt one by one fully automatic. A registration camera will control the position of the screen and the film. The image is printed, and the film will automatically pass through the oven.

UV-inks are cured using UV-light, solvent-based inks are thermally cured ,often in combination with infrared light.

Why it is so important to have the right operator

At Quad industries we understand screen printing is a precise and highly skilled process. Our printers need to have an eye for detail to deliver perfect print results. We insist that our screen printers know the exact techniques and parameters needed to achieve the highest quality result possible. You need an affinity with electronics, and you need to understand why the print result is more critical in comparison to graphical screen printing.

Our screen printers understand the intricacies of screen printing, including controlling tension in the mesh and adjusting settings such as exposure time, flood amount and squeegee pressure. They also know how to apply different types of inks – solvent-based or UV-curable – on various substrates such as PET, TPU and PC.

We use fully automatic printing lines that achieve from 500 to 1000 print runs per hour. So having the right operator at your side that controls the process completely, knows how to solve issues that arise and doesn’t waste material and produces effective electronic circuits, is very important. Troubleshooting screen printing problems can be tricky as it involves a lot of factors. The most common issue with screen printing is that the print result is not accurate or consistent. To troubleshoot screen printing issues, you must look at all aspects of the process: screen tension, ink type and viscosity, screen mesh size, flood bar speed and pressure applied by squeegee.

At Quad Industries, we have the right operators with an eye for detail, and we use cutting-edge screen-printing technologies to ensure prints are accurate and consistent. Our process is flexible enough to accommodate a wide range of substrates and inks, enabling us to produce the highest quality electronic circuits at competitive prices.

We understand screen printing comes with its own set of challenges, which is why it’s important to have experienced screen printers on hand who can troubleshoot any issues that may arise. With our knowledge and expertise, your printed circuit boards will be perfect every time. Not convinced? Just challenge us.